35 Ton Double Hook Bridge Crane with 5 Ton Auxiliary hook Crane

35 ton /5 ton double hook bridge crane for sale Philippines. Double girder overhead crane with35 ton Main hook & 5 Ton Auxiliary hook Crane, remote control.

| Crane type | Double girder overhead crane with European style |

| Crane specifications | 35 ton Main hook & 5 Ton Auxiliary hook |

| Lifting Height | 10 m |

| Crane Span | 8.49m |

| Power supply | 400V/60Hz/3 PH |

Category: Euro Hoist Crane

Your Trusted Overhead Crane Manufacturer & Supplier

35 ton /5 ton double hook bridge crane for sale Philippines

35 Ton Double Hook Bridge Crane with 5 Ton Auxiliary hook Crane

35 ton /5 ton double hook bridge crane for sale Philippines. Double girder overhead crane with3 5 ton Main hook & 5 Ton Auxiliary hook Crane, remote control.

Overview of 35 ton /5 ton double hook bridge crane for sale Philippines

- Crane type: 35 ton double girder overhead crane with 5 ton auxiliary hook

- Crane capacity: 35t/5 ton

- Crane span: 49m

- Crane lifting height: 10m

- Crane power supply: 400V60HZ/3Phase

- Project location: Philippines

Double Hook Overhead Crane with 35 ton Main hook & 5 Ton Auxiliary hook Crane

35Ton /5 Ton Double Hook Bridge Crane is designed for a client in the Philippines. This case study highlights the successful implementation of a 35-ton double girder overhead crane with a 5-ton auxiliary hook in the Philippines. The bridge crane was selected to meet the material handling needs of a manufacturing facility, focusing on its impressive lifting capacity, reliable performance, and remote control capabilities. The project's successful execution significantly improved the productivity and safety of the material handling operations, leading to a positive impact on the company's overall efficiency.

Back ground of 35 ton /5 ton double hook bridge cranes

In response to the increasing demand for efficient material handling solutions in the Philippines, a leading manufacturing company sought to acquire a reliable and robust crane system to streamline their operations. After careful evaluation of various options, they decided to invest in a 35-ton double girder overhead crane with a 5-ton auxiliary hook. The crane offered superior lifting capacity, flexible configuration, and advanced control features that aligned perfectly with the company's requirements.

The primary aims of the double hook bridge crane project were as follows:

- Enhance Material Handling Capacity: The company aimed to increase its material handling capacity significantly by investing in a crane with a high lifting capacity.

- Improve Productivity: The new crane was expected to expedite loading and unloading processes, reducing downtime and improving overall productivity.

- Ensure Safety: Safety was a top priority for the company. They sought a crane that adhered to the highest safety standards, minimizing the risk of accidents during lifting operations.

- Remote Control Capability: The ability to control the crane remotely was essential for optimizing material handling operations and allowing operators to work from a safe distance.

Double hook bridge crane design and specification confirmation

The selection process involved collaboration between the company's engineering team and crane specialists. They assessed various crane options available in the market, considering factors like lifting capacity, safety features, reliability, and after-sales support. The 35-ton double hook bridge crane with an auxiliary hook stood out as the most suitable solution.

Crane Specifications:

- Crane Type: 35-ton double girder overhead crane with a 5-ton auxiliary hook

- Crane Capacity: Main Hook 35 tons, Auxiliary Hook 5 tons

- Crane Span: 49 meters

- Crane Lifting Height: 10 meters

- Crane Power Supply: 400V, 60Hz, 3 Phase

Productions of 35 ton/5 ton double hook bridge crane

Double hook built up hoist trolley

35 ton / 5 ton double hook hoist trolley - Euroepan style crane hoist for sale

Double hook built up hoist trolley 35 ton/ 5 ton

A build-up double hook hoist with European style is a type of lifting equipment commonly used in industrial applications. It is known for its robust construction, advanced features, and adherence to European safety and quality standards. Below are some of the key features of a build-up double hook hoist with European style:

- Dual Hook System: The primary feature of this hoist is its double hook configuration, allowing it to lift and transport two separate loads simultaneously. This feature enhances productivity by enabling the hoist to handle multiple tasks in a single operation.

- Modular Design: The European style build-up double hook hoist often comes with a modular design, making it easy to assemble and disassemble. This feature simplifies maintenance and repair tasks, reducing downtime and improving overall efficiency.

- High Lifting Capacity: These hoists are designed to handle heavy loads with ease. They come with a high lifting capacity, making them suitable for various industrial applications that involve lifting and transporting substantial weights.

- Smooth and Precise Operation: European style hoists are engineered for smooth and precise operation. They incorporate high-quality components and advanced control systems to ensure accurate positioning and controlled movements.

electrical box of double girder overhead crane with double hooks

- Variable Speed Control: Many build-up double hook hoists with European style offer variable speed control for both the main hook and auxiliary hook. This feature allows operators to adjust the lifting speed based on the load's weight and position, ensuring safe and efficient handling.

- Safety Features: Safety is paramount in European-style hoists, and they typically come equipped with multiple safety features. These may include overload protection, emergency stop buttons, limit switches to prevent over-travel, and safety brakes to hold the load securely.

- Remote Control: European hoists often come with advanced remote control capabilities, enabling operators to control the hoist from a safe distance. This feature improves safety during lifting operations and provides better visibility for the operator.

- Low Maintenance Requirements: The hoist's design and use of high-quality components result in reduced maintenance needs and extended service life. Regular inspections and servicing ensure that the hoist operates reliably and safely over the long term.

- Conforms to European Standards: A significant advantage of European-style hoists is their compliance with strict European safety and quality standards, such as the European Machinery Directive and EN standards. This conformity ensures that the hoist meets the highest safety and performance requirements.

- Application Versatility: Build-up double hook hoists with European style find application in a wide range of industries, including manufacturing, construction, shipbuilding, and more. Their versatility makes them suitable for various lifting tasks and environments.

In conclusion, a build-up double hook hoist with European style offers a reliable and efficient solution for heavy-duty lifting applications. Its double hook configuration, safety features, remote control capabilities, and adherence to European standards make it a popular choice for industries seeking advanced and high-performance lifting equipment.

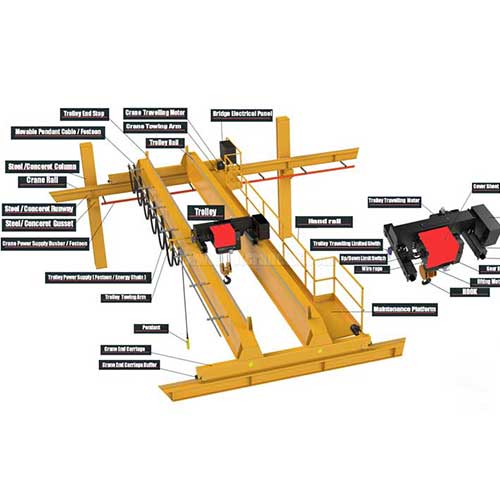

Box girder and end carriages

box girder of double hook overhead crane with 35 ton main hook and 5 ton auxiliary hook block

box girder and end carriages of main hook and auxiliary hook block overhead cranes

Box Girder:

The box girder used in double girder double hook bridge cranes offers a sturdy and durable construction with a closed rectangular cross-section. This design provides excellent load-bearing capacity and structural integrity, making it ideal for handling heavy loads efficiently. Despite its strength, the box girder is relatively lightweight, allowing for optimal utilization of the crane's lifting capacity for the actual load. Its closed-box structure ensures improved resistance to deflection, resulting in precise and stable load movements. Additionally, the closed design provides better protection for internal components, reducing maintenance requirements and offering an aesthetically pleasing appearance to the crane.

End Carriages:

The end carriages of double girder double hook bridge cranes are equipped with wheels that run on the crane runway rails, facilitating smooth and efficient lateral movement along the bridge. Heavy-duty bearings ensure seamless wheel operation, while geared motors power the lateral motion. End carriages may include motor brakes for secure holding when the crane is not in use and limit switches to prevent over-travel, enhancing safety during crane operation. With proper wheel alignment, wear and tear on the crane runway rails are minimized, extending their lifespan. Easy access to components in the end carriages simplifies maintenance and inspection tasks, ensuring the crane's reliability and longevity.

Benefits of 35 ton double hook bridge cranes with 5 ton auxiliary hook block

The deployment of the 35-ton double hook bridge crane with a 5-ton auxiliary hook yielded remarkable results for the company:

The double hook design in bridge cranes offers several benefits, making it a preferred choice in certain lifting applications. Some of the key advantages of using a double hook design are as follows:

- Increased Lifting Efficiency: With two hooks, a double hook bridge crane can lift and transport two separate loads simultaneously. This feature significantly improves lifting efficiency and reduces the number of lifting cycles required to handle multiple loads. It can lead to time savings and increased productivity in material handling operations.

- Versatility: Double hook bridge cranes are versatile and suitable for handling various load configurations. The ability to lift multiple loads independently or in tandem offers flexibility in material handling tasks.

- Load Balancing: In some scenarios where loads may not be evenly distributed, using a double hook design can help balance the load more effectively. This feature is especially useful in applications where maintaining load stability during lifting is critical.

- Multi-Point Lifting: The double hook design allows the crane to lift and place objects at different points simultaneously. This capability is valuable when precise placement of loads at specific locations is required, optimizing the material handling process.

- Reduced Downtime: By lifting and transporting two loads simultaneously, the crane can complete more work in less time. This efficiency can lead to reduced downtime and improved overall operational efficiency.

- Enhanced Productivity: The faster loading and unloading processes enabled by the crane resulted in reduced production downtime, leading to improved overall productivity.

- Optimal Safety: The crane's advanced safety features, combined with remote control capability, allowed operators to conduct lifting operations from a safe distance, minimizing the risk of accidents.

- Cost Savings: The efficient material handling process translated into cost savings as the company could manage its operations with fewer resources.

When to Use Double Hook Bridge Cranes:

While double hook bridge cranes offer various benefits, they are not universally suitable for all applications. The decision to use a double hook bridge crane depends on specific lifting requirements and operational needs. Here are some situations where using a double hook bridge crane is advantageous:

- Handling Multiple Loads: Double hook bridge cranes are ideal for facilities that frequently need to handle multiple loads at the same time. Industries such as steel mills, shipyards, and material processing plants often deal with multiple loads simultaneously, making double hook cranes a valuable asset.

- Load Balancing: When lifting asymmetric or unbalanced loads, a double hook design can help distribute the weight more evenly between the hooks, enhancing load stability and reducing the risk of accidents.

- Improved Productivity: In operations where lifting and transporting large quantities of materials are essential, a double hook bridge crane can significantly boost productivity by reducing the time required for lifting tasks.

- Precise Placement: For applications that require accurate and precise placement of loads, the ability to control each hook independently allows for more controlled and synchronized movements.

- Space Constraints: In facilities with limited space, a double hook bridge crane can be an efficient solution, as it can handle multiple tasks without the need for additional equipment.

It's important to note that double hook bridge cranes may have higher initial costs and require skilled operators to handle the simultaneous lifting operations safely. Therefore, careful consideration of the specific lifting requirements and operational needs is essential before opting for a double hook design in bridge cranes.

Typical applications of double hook bridge cranes

A double hook bridge crane with an auxiliary hook is a versatile lifting equipment that can be beneficial in various scenarios where multiple lifting tasks need to be performed simultaneously or with different load configurations. Here are some examples of when to use a double hook bridge crane with auxiliary hooks:

- Steel Fabrication and Handling: In steel fabrication facilities, double hook bridge cranes with auxiliary hooks can be used to handle large steel plates or beams simultaneously. The main hook can lift the primary load, while the auxiliary hook can handle smaller pieces or accessories, streamlining the material handling process.

- Shipbuilding Industry: Shipyards often require cranes with multiple hooks to lift and position different ship components during construction. Double hook bridge cranes with auxiliary hooks are ideal for these applications, as they allow for efficient assembly and fitting of various ship parts.

- Construction Sites: Construction projects may involve lifting and placing multiple materials, such as concrete blocks, steel reinforcements, and construction equipment. Double hook bridge cranes can speed up the process by enabling operators to handle different loads concurrently.

- Manufacturing Facilities: Manufacturing plants dealing with large and complex products may benefit from double hook bridge cranes with auxiliary hooks. For example, in the aerospace industry, these cranes can help assemble aircraft components efficiently.

- Foundries: Foundries often deal with heavy molten metal loads and various molds. Double hook bridge cranes with auxiliary hooks can be used to lift the molds and handle additional equipment or tools concurrently, improving workflow.

- Material Processing Plants: Material processing plants handling bulk materials or aggregates can use double hook bridge cranes with auxiliary hooks to load/unload different materials simultaneously.

- Handling Containers: At ports or container terminals, double hook bridge cranes with auxiliary hooks can be used to lift and transport multiple containers at once, enhancing container handling efficiency.

- Rigging Operations: In rigging and construction projects, a double hook bridge crane can be used to lift and position heavy equipment while simultaneously handling rigging materials or tools.

- Power Plants: Double hook bridge cranes with auxiliary hooks are valuable in power plants for handling heavy equipment during maintenance or installation, allowing for multitasking during critical operations.

- Warehouse Operations: In large warehouses or distribution centers, double hook bridge cranes with auxiliary hooks can facilitate the handling of multiple pallets or packages at the same time.

These examples demonstrate how the versatility of a double hook bridge crane with auxiliary hooks can significantly improve productivity, efficiency, and safety in various industrial applications that involve simultaneous or different lifting tasks. However, it's essential to assess the specific requirements and operational needs of each application to determine if this type of crane configuration is the best fit.

The successful implementation of the 35-ton double hook bridge crane with a 5-ton auxiliary hook proved to be a game-changer for the manufacturing company in the Philippines. The crane's exceptional lifting capacity, safety features, and remote control capability significantly improved material handling efficiency, productivity, and safety. This case study demonstrates how investing in the right material handling equipment can yield substantial benefits for industrial operations.

Get Your Custom Overhead Crane

The necessary parameters for a custom double hook bridge crane:

- Lifting Capacity

- Span Length

- Lifting Height

- Duty Class

- Control Method

- Travel Speeds

- Safety Features

- Power Supply

- Environmental Conditions

- Compliance with Standards

- Budget and Timeline

These parameters will provide the essential information required to design and manufacture a custom double hook bridge crane that fits your specific material handling needs and operational requirements.

Main Projects

Related Products

6.3 ton overhead crane kit for sale Philippines, complete single girder top running overhead crane system, low headroom design for workshop indoor use.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch